DIY Acrylc Sump or DT - same thing

4 posters

Page 1 of 1

DIY Acrylc Sump or DT - same thing

DIY Acrylc Sump or DT - same thing

I'm starting my 200gal build and starting with the sump first. I will show you how I do it and most of the pro tank builders do it. Yes it's not a Nano, but building is the same way for small 1 gallon to 500 gallons.

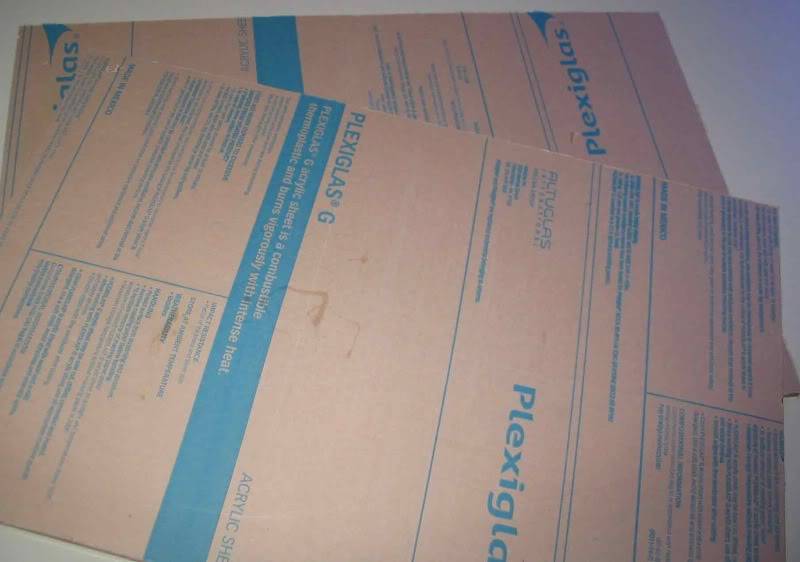

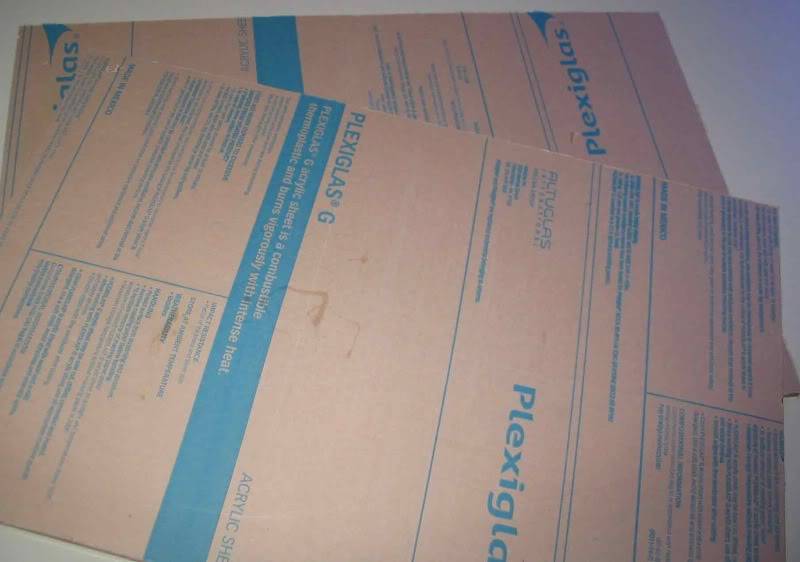

The sump is about a 79gal measures 49 3/4"L x 24"W x 16"H. I used oversize sheet of 3/8" Plex "G" which is 50"x99", great for those who have to have a 24" deep tank (inside dimensions)

On with the build.

The plans, gotta have a map of what you want, where it's gonna go and if it'll fit or not.

I didn't take any pix's of the cutting as I have my wholesaler do that. But the routing is the next step

My router table, I have a total of 3 leafs if i need the room for those longer tanks

The working end

What's left after routing, a big mess that sticks to everything. Too bad I can't melt this and make a sheet of plastic

The ends pieces

The baffles

The front and back and top and bottom pieces

The filter Sock Holder

The tools:

Start the build:

Starting on one end of the sump

I use these 45's to hold the acrylic at a 90' and have about 6 of these made up and sometimes have to use all six of them. (forgot to take pix of that :roll_eyes:)

The pins method of assembling acrylic. These are acupuncture needles that I use and are about the right size. I use to use those tie wraps from the produce section but they were too thick (big around)

The magic juice - combination of Weldon #4 and *%$@#&*^.

Shims, these single edged razors work the best for slipping under the acrylic, thin enough but you can stack them when you need them. You need some type of shim to keep the acrylic edges together for no bubble seams (as well as the routed edge)

more to come

The sump is about a 79gal measures 49 3/4"L x 24"W x 16"H. I used oversize sheet of 3/8" Plex "G" which is 50"x99", great for those who have to have a 24" deep tank (inside dimensions)

On with the build.

The plans, gotta have a map of what you want, where it's gonna go and if it'll fit or not.

I didn't take any pix's of the cutting as I have my wholesaler do that. But the routing is the next step

My router table, I have a total of 3 leafs if i need the room for those longer tanks

The working end

What's left after routing, a big mess that sticks to everything. Too bad I can't melt this and make a sheet of plastic

The ends pieces

The baffles

The front and back and top and bottom pieces

The filter Sock Holder

The tools:

Start the build:

Starting on one end of the sump

I use these 45's to hold the acrylic at a 90' and have about 6 of these made up and sometimes have to use all six of them. (forgot to take pix of that :roll_eyes:)

The pins method of assembling acrylic. These are acupuncture needles that I use and are about the right size. I use to use those tie wraps from the produce section but they were too thick (big around)

The magic juice - combination of Weldon #4 and *%$@#&*^.

Shims, these single edged razors work the best for slipping under the acrylic, thin enough but you can stack them when you need them. You need some type of shim to keep the acrylic edges together for no bubble seams (as well as the routed edge)

more to come

lemonyx- Fish Fry

- Posts : 7

Reputation : 0

Join date : 2010-04-23

Age : 71

Location : Portland,OR

Re: DIY Acrylc Sump or DT - same thing

Re: DIY Acrylc Sump or DT - same thing

Start the build:

Starting on one end of the sump

I use these 45's to hold the acrylic at a 90' and have about 6 of these made up and sometimes have to use all six of them. (forgot to take pix of that :roll_eyes:)

The pins method of assembling acrylic. These are acupuncture needles that I use and are about the right size. I use to use those tie wraps from the produce section but they were too thick (big around)

The magic juice - combination of Weldon #4 and *%$@#&*^.

Shims, these single edged razors work the best for slipping under the acrylic, thin enough but you can stack them when you need them. You need some type of shim to keep the acrylic edges together for no bubble seams (as well as the routed edge)

more to come

Starting on one end of the sump

I use these 45's to hold the acrylic at a 90' and have about 6 of these made up and sometimes have to use all six of them. (forgot to take pix of that :roll_eyes:)

The pins method of assembling acrylic. These are acupuncture needles that I use and are about the right size. I use to use those tie wraps from the produce section but they were too thick (big around)

The magic juice - combination of Weldon #4 and *%$@#&*^.

Shims, these single edged razors work the best for slipping under the acrylic, thin enough but you can stack them when you need them. You need some type of shim to keep the acrylic edges together for no bubble seams (as well as the routed edge)

more to come

lemonyx- Fish Fry

- Posts : 7

Reputation : 0

Join date : 2010-04-23

Age : 71

Location : Portland,OR

Re: DIY Acrylc Sump or DT - same thing

Re: DIY Acrylc Sump or DT - same thing

More sump

Spacing out the baffles and making sure they are perpendicular to the bottom. I'm using a 2" pvc pipe which comes out to 2 3/8" spacing between baffles.

All 4 baffles in place, decided not to split the fuge area and will it will be just the baffles.

Before I go any further, I just remembered that I need probe holders so went looking thru my scrap pile and this is what the out come is.

Hummm black or white thumb screws? I used the black ones.

I like to use my "head" to work smarter and not harder (lazyness) but I use the electric drill/driver to tap all of my holes and have had no problems. There will be some who have not done this or think that they "know it all" and will chime in and say it'll break, won't work ect ect ... If you use the right drill size for the tap, it'll work.

Ok enough of that.

So I made two of them, the shorter one is the prob holder for my AquaController, just checking Temp and PH for now. The longer one is for the ATO and will need to make another probe holder as the blank end will hold the float switch for the ATO and instead of a Calcium Reactor I will be using the "[URL="http://www.h2oplusomething.com/index.php?option=com_content&view=article&id=69:inside-the-balling-light-method-&catid=34:sps-keeping&Itemid=64"]Balling[/URL]" method kind of, and will be dosing Cal, Alk, MAG and whatever else the tank needs so will need another "long" probe holder for three set's of lines.

The first half of the sump is done, now just need to turn it over and start the other side.

(I forgot to mention that the tops of the baffles the corners have been routed or chamfered to take the sharp corner off. If this is not done, it won't feel good. Plus it dresses it up showing the time put into the project)

So the order in which to assemble a tank, sump or whatever is about the same. Start on one side, stand all your vertical pieces and "glue" (actually it a solvent so it softens the plastic then bonds) of if you have any dividers then that would go first, (horizontal piece that spans between the verticals) then starting on one "end" start gluing them down, making sure you have a right angle jig to keep it nice and straight and some type of spacer for your baffle spacing. (is that clear - I think I just babbled)

more to come

Spacing out the baffles and making sure they are perpendicular to the bottom. I'm using a 2" pvc pipe which comes out to 2 3/8" spacing between baffles.

All 4 baffles in place, decided not to split the fuge area and will it will be just the baffles.

Before I go any further, I just remembered that I need probe holders so went looking thru my scrap pile and this is what the out come is.

Hummm black or white thumb screws? I used the black ones.

I like to use my "head" to work smarter and not harder (lazyness) but I use the electric drill/driver to tap all of my holes and have had no problems. There will be some who have not done this or think that they "know it all" and will chime in and say it'll break, won't work ect ect ... If you use the right drill size for the tap, it'll work.

Ok enough of that.

So I made two of them, the shorter one is the prob holder for my AquaController, just checking Temp and PH for now. The longer one is for the ATO and will need to make another probe holder as the blank end will hold the float switch for the ATO and instead of a Calcium Reactor I will be using the "[URL="http://www.h2oplusomething.com/index.php?option=com_content&view=article&id=69:inside-the-balling-light-method-&catid=34:sps-keeping&Itemid=64"]Balling[/URL]" method kind of, and will be dosing Cal, Alk, MAG and whatever else the tank needs so will need another "long" probe holder for three set's of lines.

The first half of the sump is done, now just need to turn it over and start the other side.

(I forgot to mention that the tops of the baffles the corners have been routed or chamfered to take the sharp corner off. If this is not done, it won't feel good. Plus it dresses it up showing the time put into the project)

So the order in which to assemble a tank, sump or whatever is about the same. Start on one side, stand all your vertical pieces and "glue" (actually it a solvent so it softens the plastic then bonds) of if you have any dividers then that would go first, (horizontal piece that spans between the verticals) then starting on one "end" start gluing them down, making sure you have a right angle jig to keep it nice and straight and some type of spacer for your baffle spacing. (is that clear - I think I just babbled)

more to come

lemonyx- Fish Fry

- Posts : 7

Reputation : 0

Join date : 2010-04-23

Age : 71

Location : Portland,OR

Re: DIY Acrylc Sump or DT - same thing

Re: DIY Acrylc Sump or DT - same thing

The first end piece is on, the baffles

now the other end piece

The needles are only used for the "outside" or parameter of the tank or sump in this case.

Now what I have is a "U"(end pieces)with finger in between (baffles). Now is the time to ready the other "side" of the tank/sump.

The paper is removed and it's slid under, then the finished part is turned over and aligned onto the bottom piece. (I hope that is clear, as mud probably)

The first assembly with the end's and baffles are just turned upside down on to the next piece, lined up and "glued" on.

now the needles and shims are used to line up the "joints for gluing.

Now the "bottom of the sump.

So the finished "carcass" has a front, back and the baffles, just needs the bottom and then the top.

Bottom first

I use a needle every 6" and a shim if needed - all around the parameter of the sump. This take a little time and can mean bubbles or a nice clear seam.

When you are ready, apply the glue on one side, go back and pull the needles and push the shim in a little, you can see the solvent being squeezed out

so you have to stop or you'll get a "dry joint"

Repeat for the next 3 sides, add a little weight on top and let it dry

The top is next - has to be routed and have not decided on the shape of the opening as yet.

now the other end piece

The needles are only used for the "outside" or parameter of the tank or sump in this case.

Now what I have is a "U"(end pieces)with finger in between (baffles). Now is the time to ready the other "side" of the tank/sump.

The paper is removed and it's slid under, then the finished part is turned over and aligned onto the bottom piece. (I hope that is clear, as mud probably)

The first assembly with the end's and baffles are just turned upside down on to the next piece, lined up and "glued" on.

now the needles and shims are used to line up the "joints for gluing.

Now the "bottom of the sump.

So the finished "carcass" has a front, back and the baffles, just needs the bottom and then the top.

Bottom first

I use a needle every 6" and a shim if needed - all around the parameter of the sump. This take a little time and can mean bubbles or a nice clear seam.

When you are ready, apply the glue on one side, go back and pull the needles and push the shim in a little, you can see the solvent being squeezed out

so you have to stop or you'll get a "dry joint"

Repeat for the next 3 sides, add a little weight on top and let it dry

The top is next - has to be routed and have not decided on the shape of the opening as yet.

lemonyx- Fish Fry

- Posts : 7

Reputation : 0

Join date : 2010-04-23

Age : 71

Location : Portland,OR

Re: DIY Acrylc Sump or DT - same thing

Re: DIY Acrylc Sump or DT - same thing

Great job! I go it for the most part. My question is, will the joints of themselves be strong enough to hold the whole sump together? Or do you have other ideas for support?

Hero- Site Admin

- Posts : 3231

Reputation : 0

Join date : 2009-04-04

Location : San Diego, CA

Re: DIY Acrylc Sump or DT - same thing

Re: DIY Acrylc Sump or DT - same thing

For this height of a sump 16" the 3/8" thickness without a top will be fine, so yes on your question. But I will have a top with Euro brace around it and that will be the next installment.

lemonyx- Fish Fry

- Posts : 7

Reputation : 0

Join date : 2010-04-23

Age : 71

Location : Portland,OR

Re: DIY Acrylc Sump or DT - same thing

Re: DIY Acrylc Sump or DT - same thing

Ahh i see. It's good that you are so good a DIY stuff, i am at a complete loss when it comes to complex stuff. Are you doing the 200 in a similar manner?

Welcome to the forum by the way, we seem to get a lot of traffic from the pacific corridor.

Welcome to the forum by the way, we seem to get a lot of traffic from the pacific corridor.

Hero- Site Admin

- Posts : 3231

Reputation : 0

Join date : 2009-04-04

Location : San Diego, CA

Re: DIY Acrylc Sump or DT - same thing

Re: DIY Acrylc Sump or DT - same thing

What is the status of the build?

Hero- Site Admin

- Posts : 3231

Reputation : 0

Join date : 2009-04-04

Location : San Diego, CA

Re: DIY Acrylc Sump or DT - same thing

Re: DIY Acrylc Sump or DT - same thing

nice build. I tlooks similiar to the mess I made with my leds. Except we were cutting sheets of aluminum and pouring silver thermal compound and solder flux all over the place.

Rambo- Starry Flounder

- Posts : 321

Reputation : 0

Join date : 2010-01-12

Location : Louisiana

Re: DIY Acrylc Sump or DT - same thing

Re: DIY Acrylc Sump or DT - same thing

real nice! Looking forward to the finished product.

~ocean- Moderator

- Posts : 838

Reputation : 0

Join date : 2009-09-27

Location : Stoon

Re: DIY Acrylc Sump or DT - same thing

Re: DIY Acrylc Sump or DT - same thing

I think we all are  .

.

Hero- Site Admin

- Posts : 3231

Reputation : 0

Join date : 2009-04-04

Location : San Diego, CA

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum